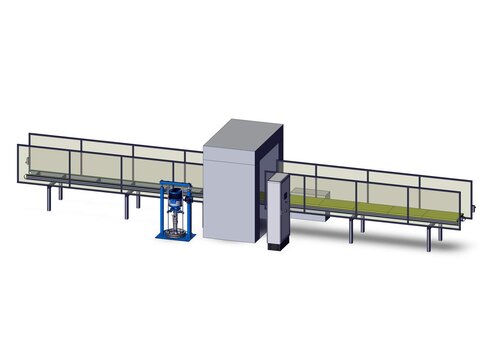

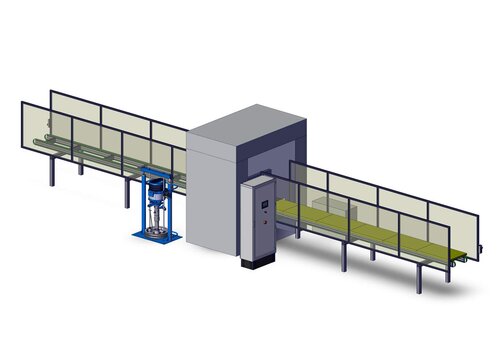

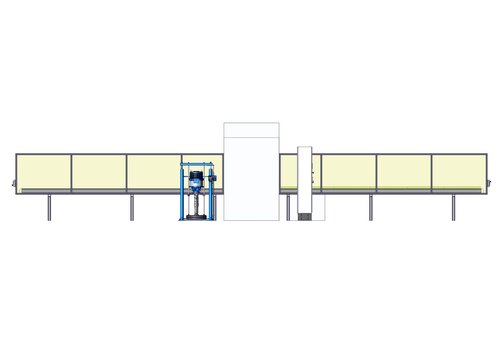

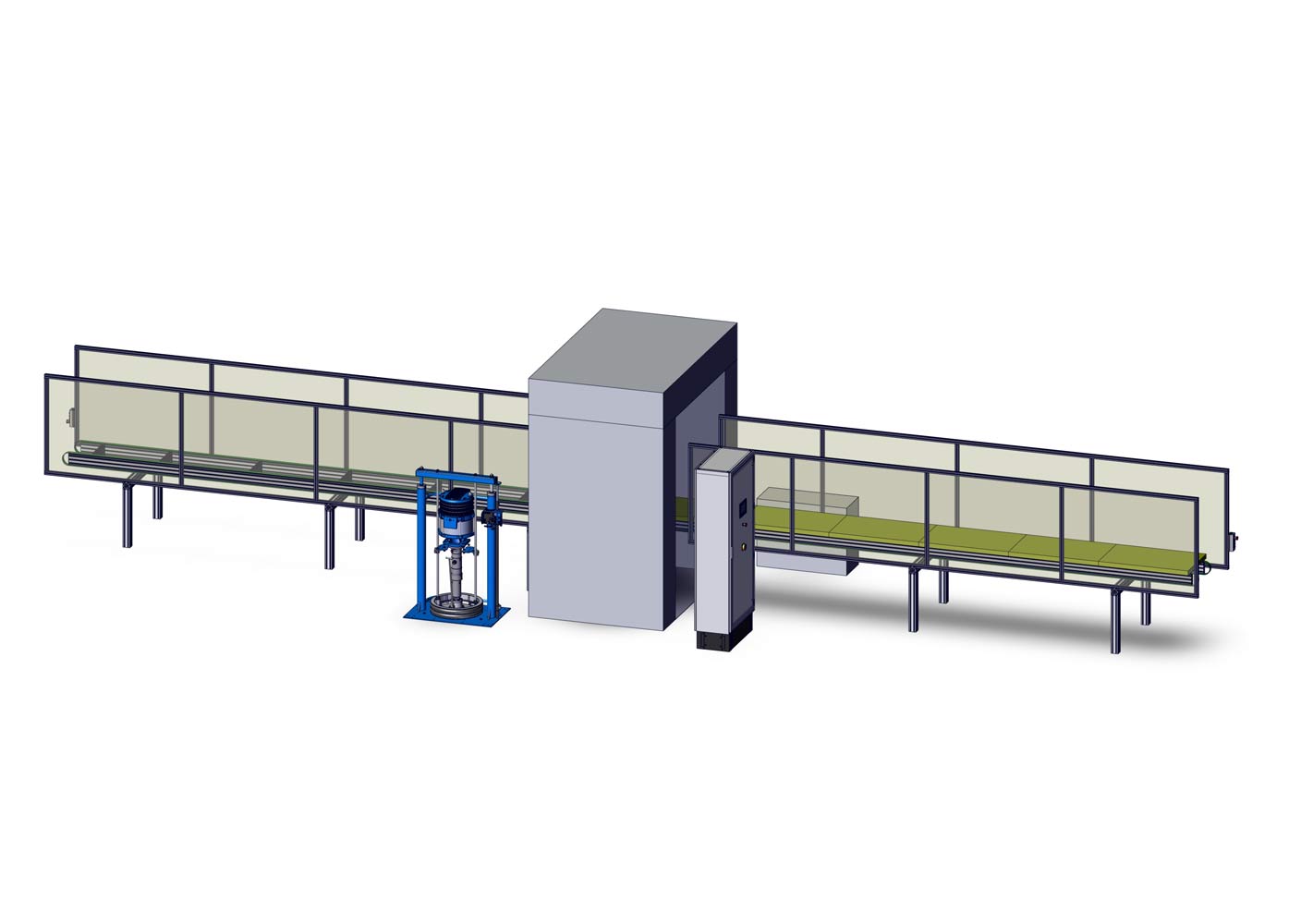

Semi-automated continuous coating line

- Consistently high application quality

- Little overspray due to integrated extraction housing

- Modular set-up and expansion according to customer process specifications

Description

Uninterrupted coating with consistent application quality.

In response to a customer request for a system concept for the automated application of a fire protection coating on mineral fiber boards, we developed a semi-automated concept for a continuous coating system.

The components to be coated were placed on the corresponding feed line in cyclical operation so that the subsequent coating process could run through the application bar without interruption. This ensured a consistent coating thickness as well as a uniform spray pattern. The integrated suction housing contained the overspray generated during application and ensured sufficient ventilation of the application area.

At the customer's request, assemblies can be extended and expanded via the modular design, thereby increasing the system capacity. This can be achieved, for example, by using an automatic loading and unloading system with a multi-axis gantry system (pick & place).

Uninterrupted coating with consistent application quality.

In response to a customer request for a system concept for the automated application of a fire protection coating on mineral fiber boards, we developed a semi-automated concept for a continuous coating system.

The components to be coated were placed on the corresponding feed line in cyclical operation so that the subsequent coating process could run through the application bar without interruption. This ensured a consistent coating thickness as well as a uniform spray pattern. The integrated suction housing contained the overspray generated during application and ensured sufficient ventilation of the application area.

At the customer's request, assemblies can be extended and expanded via the modular design, thereby increasing the system capacity. This can be achieved, for example, by using an automatic loading and unloading system with a multi-axis gantry system (pick & place).