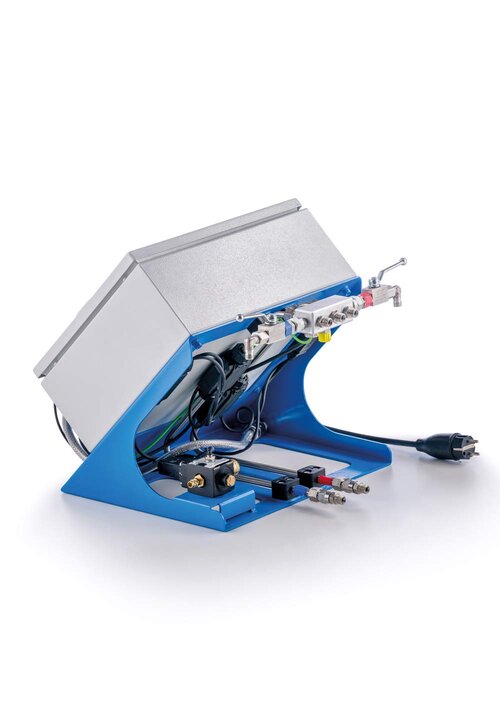

WIWA INJECT GUARD

- For injections up to 400 bar

- Suitable for all WIWA 2K injection devices

- Provides process reliability and cost optimization through control of consumption quantities and injection pressures

Description

Optimized workflows and full cost control.

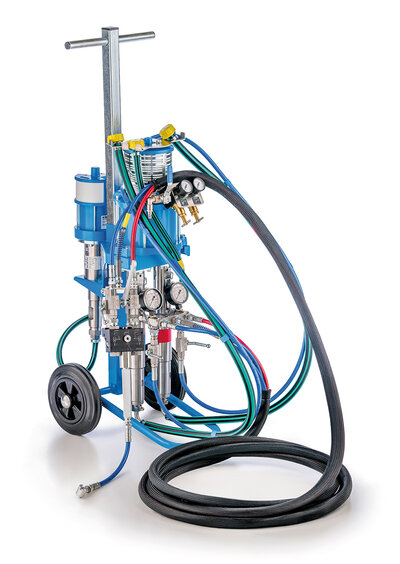

You can view the materials processed and the associated injection pressures at any time on your mobile device in the WIFI of the data logger. |n addition, the system monitors the mixing ratio and warns of irregularities, e.g. due to empty containers. The control optionally signals when the maximum injection quantity or the maximum injection pressure per borehole has been reached. Operation on the 4" display directly on the control cabinet and with any terminal device with WIFI function and internet browser. Pressure at the mixer, actual quantity packer and temperature (optional) are shown in the display and mobile terminal.

Suitable accessories

Technical Data

|

Model

|

INJECT GUARD |

| Order number | 0669958 |

B - On container, D - on tripod, F - on chassis, G - on rack, H - on lift truck,

GZ - On Rack with feed funnel, W - on wall mount, ASL - suction tube, DAS - Direct suction

Optimized workflows and full cost control.

You can view the materials processed and the associated injection pressures at any time on your mobile device in the WIFI of the data logger. |n addition, the system monitors the mixing ratio and warns of irregularities, e.g. due to empty containers. The control optionally signals when the maximum injection quantity or the maximum injection pressure per borehole has been reached. Operation on the 4" display directly on the control cabinet and with any terminal device with WIFI function and internet browser. Pressure at the mixer, actual quantity packer and temperature (optional) are shown in the display and mobile terminal.

Suitable accessories

|

Model

|

INJECT GUARD |

| Order number | 0669958 |

B - On container, D - on tripod, F - on chassis, G - on rack, H - on lift truck,

GZ - On Rack with feed funnel, W - on wall mount, ASL - suction tube, DAS - Direct suction

Materials

- 2K injection resins

- Polyurethane resins

- Silicate resins

- Polyurethane injection foam resins

- PUR

- Polyurethane Combi Resins

- Polyurethane injection resins

- PUR Casting foam resins

- acid curing foams

- Acylatgele