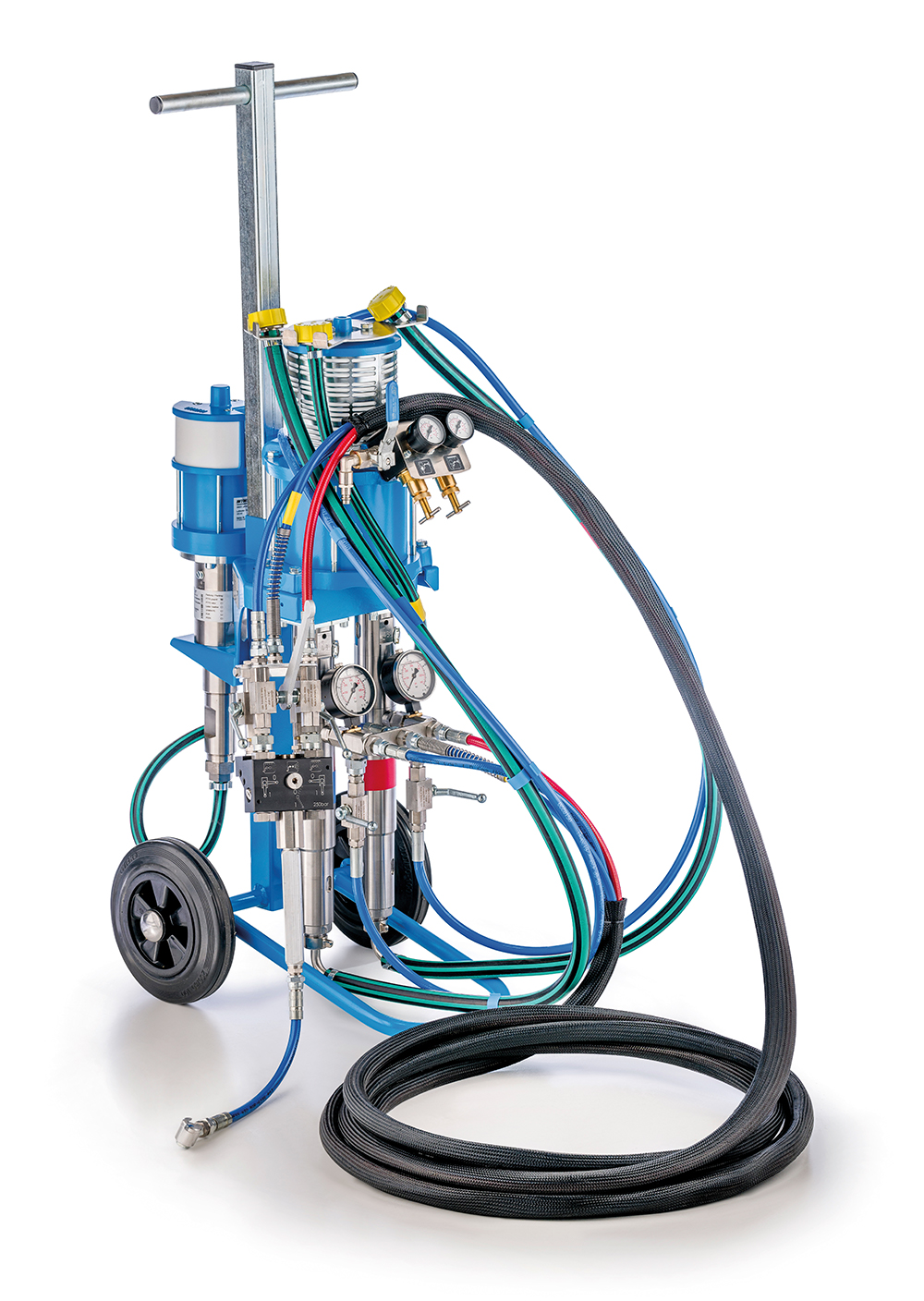

WIWA INJECT 2K 14025 GX

- Fast commissioning

- Large material inlets and check valves for viscous materials

- High mixing accuracy due to force-controlled material handling

Description

Compact and lightweight for any construction site.

The WIWA INJECT 2K 14025 GX is a pneumatic 2K piston pump with a mixing ratio of 1:1. The material pumps are connected to the air motor, so no mixing errors can occur due to the positive control. The unit is equipped with a flushing pump for cleaning the A & B components in the mixing block. The compact and lightweight design makes it particularly suitable for construction sites, even for use in inaccessible places. All material-carrying parts are made of stainless steel.

Suitable accessories

Technical Data

|

Model

|

INJECT 2K 14025 GX |

| Pressure ratio | 25:1 |

| Output per cycle | 86 ccm (2.9 fl.oz.) |

| Max. inbound air pressure | 8 bar (116 psi) |

| Max. operating pressure | 200 bar (2,901 psi) |

| Order number | 0669067 |

B - On container, D - on tripod, F - on chassis, G - on rack, H - on lift truck,

GZ - On Rack with feed funnel, W - on wall mount, ASL - suction tube, DAS - Direct suction

Fields Of Application

Mining

Building renovation

Pipes and pipelines

Building and corrosion protection

Tunnels

Building and civil engineering

Compact and lightweight for any construction site.

The WIWA INJECT 2K 14025 GX is a pneumatic 2K piston pump with a mixing ratio of 1:1. The material pumps are connected to the air motor, so no mixing errors can occur due to the positive control. The unit is equipped with a flushing pump for cleaning the A & B components in the mixing block. The compact and lightweight design makes it particularly suitable for construction sites, even for use in inaccessible places. All material-carrying parts are made of stainless steel.

Suitable accessories

|

Model

|

INJECT 2K 14025 GX |

| Pressure ratio | 25:1 |

| Output per cycle | 86 ccm (2.9 fl.oz.) |

| Max. inbound air pressure | 8 bar (116 psi) |

| Max. operating pressure | 200 bar (2,901 psi) |

| Order number | 0669067 |

B - On container, D - on tripod, F - on chassis, G - on rack, H - on lift truck,

GZ - On Rack with feed funnel, W - on wall mount, ASL - suction tube, DAS - Direct suction

Fields Of Application

Mining

Building renovation

Pipes and pipelines

Building and corrosion protection

Tunnels

Building and civil engineering