Short description

Coating of tanks for cars and trucks

Semi-automated fire protection

A French developer and integrator of robotic solutions was asked by end customers in France and Korea to supply a system for applying fire protection material to hydrogen tanks for trucks and cars. The material manufacturer involved then contacted us, which was followed by a long series of tests with him.

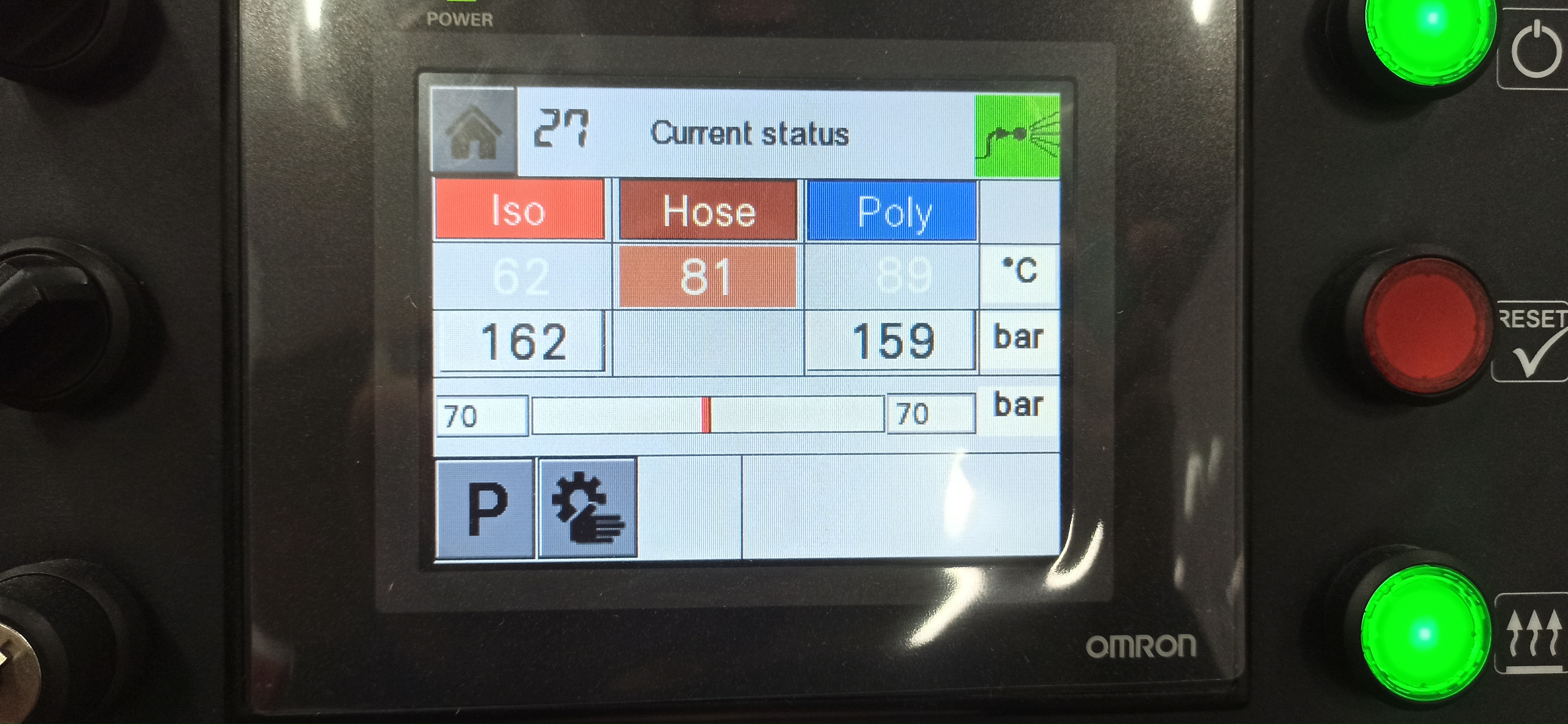

After successful completion, the system was finally put into operation in August 2022, consisting of two DUOMIX PU 540 with heated 95-liter containers and feed pumps (model 150.05), two-column lifts with agitator, additional feed pumps for the interchangeable drum and two automatic PU GUNs 4040. The guns were both attached to the same robot arm.

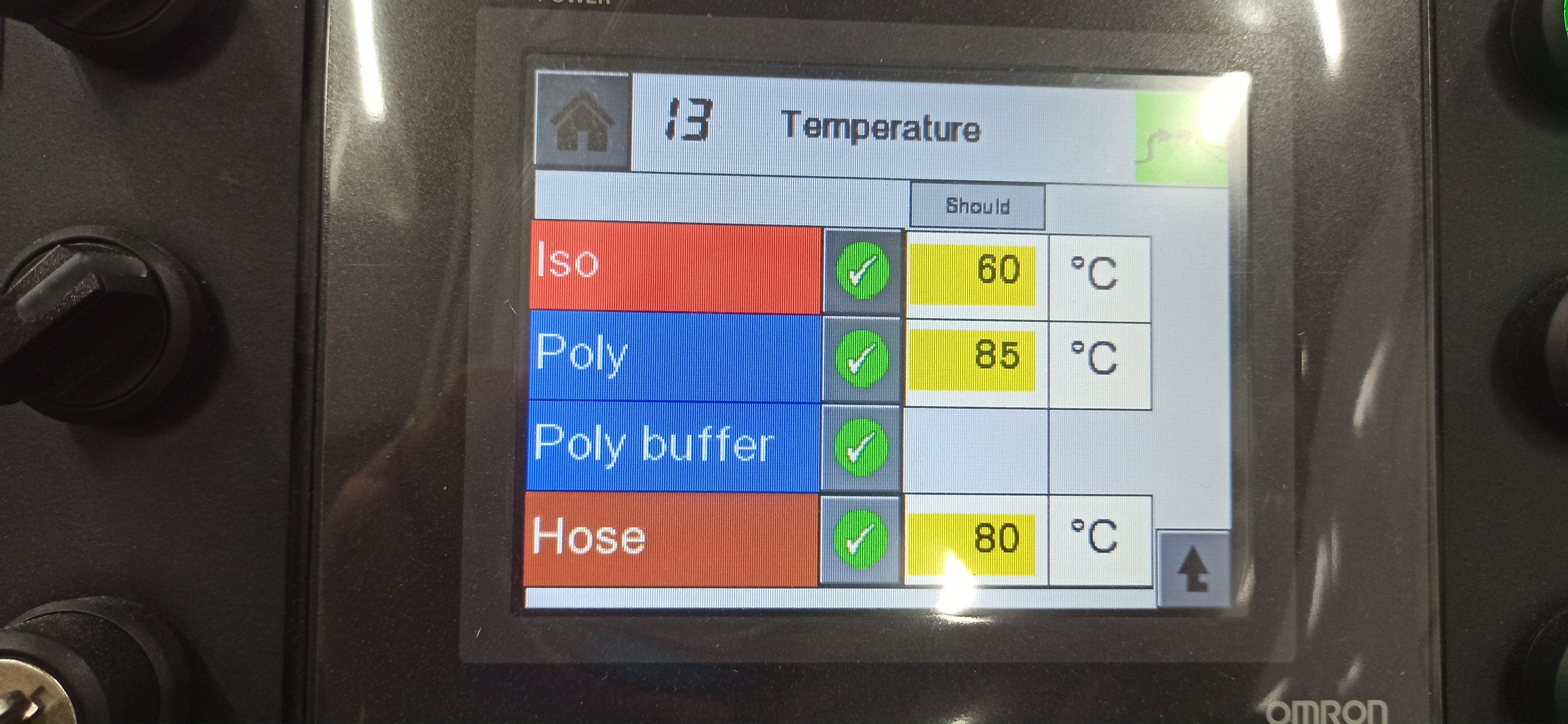

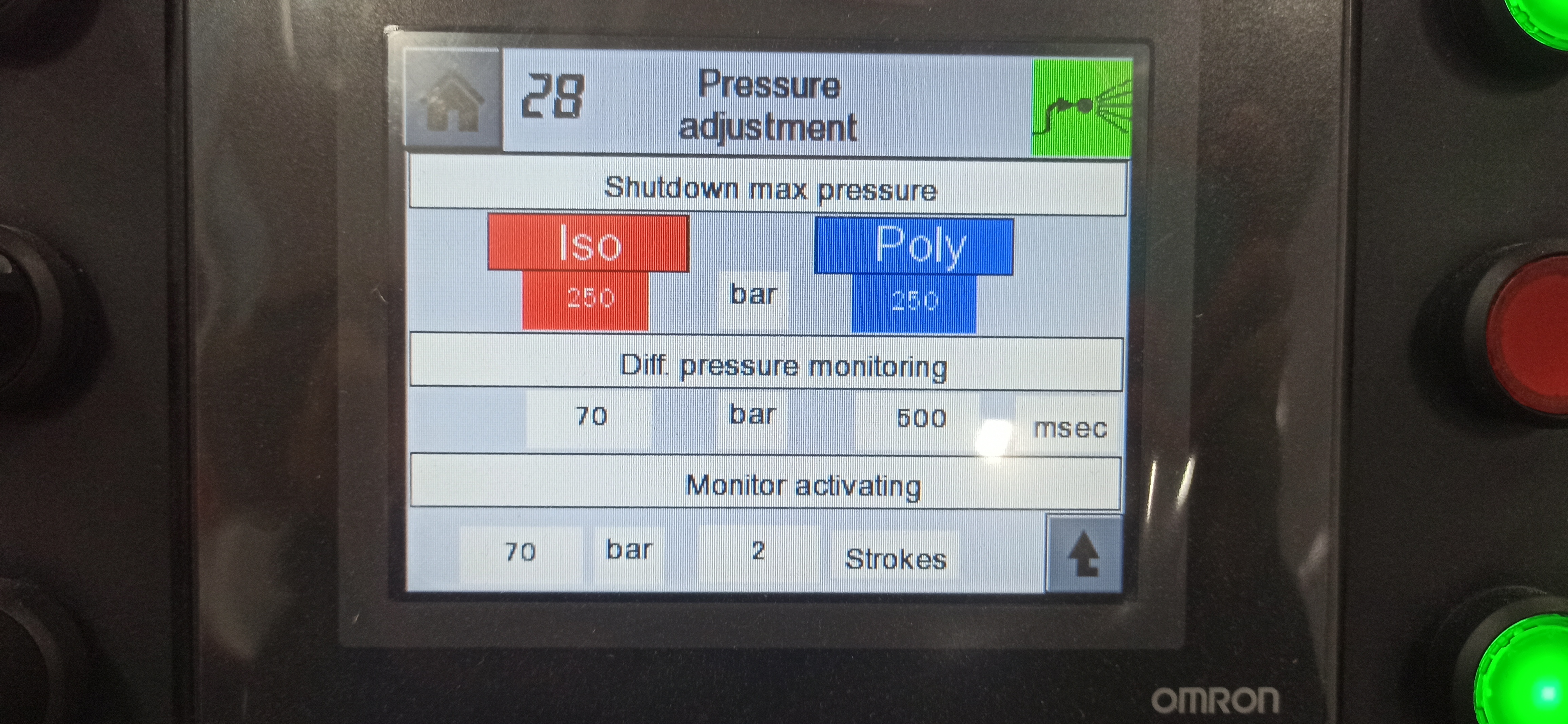

A particular challenge in this project was the very different viscosity of the two components of the material used, which was applied in a mixing ratio of 1:1 once for the primer and once as a functional layer. This resulted in a very small processing window with extremely precise temperature control. The positioning of the robot arm and the angle of attack of the guns were also of great importance in order to achieve the smoothest possible surface.

The PU GUNs 4040 were equipped with a special mixing chamber for the aforementioned viscosity differences, and the DUOMIX PU 540 ran with customer-specific software designed for a robot connection.

The order was the starting signal for many other applications.