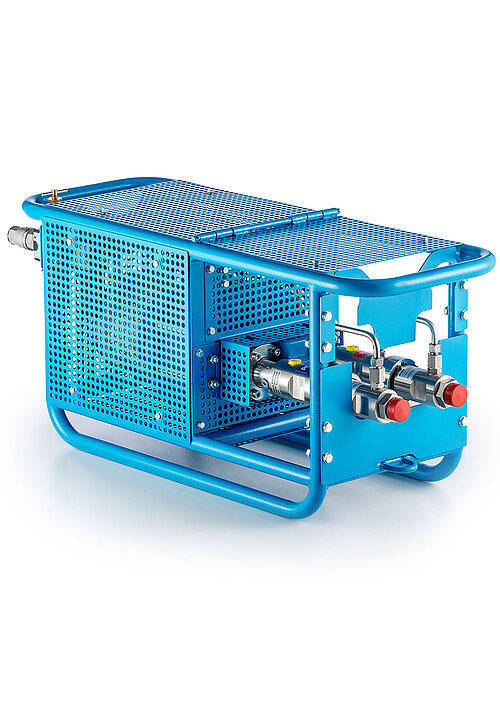

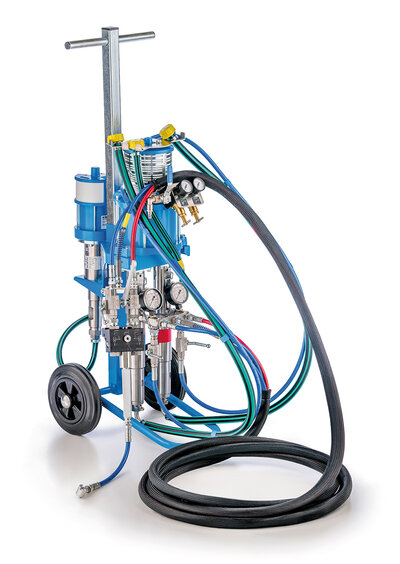

WIWA INJECT 2K 230

- Large conveying volume

- Long lengths of the hose can be adapted

- Quick start-up, easy maintenance, easy and quick cleaning

Description

Our 2K piston pump with exchangeable mixing ratio.

Due to the positive control and always the same switching points, you get the perfect dosing with the WIWA INJECT 2K 230. It is strongly characterized by its high delivery rate. In addition to the standard mixing ratio of 1:1, over 100 other mixing ratios are possible by replacing the material pumps. Aqueous and low-viscosity as well as high-viscosity materials are no problem.

Suitable accessories

Selection of project references

Technical Data

|

Model

|

INJECT 2K 230030 |

| Pressure ratio | 30:1 |

| Output per cycle | 194 ccm (6.5 fl.oz.) |

| Max. inbound air pressure | 8 bar (116 psi) |

| Max. operating pressure | 240 bar (3,481 psi) |

| Order numbers | |

| N/G | 0669709 |

| N/F | 0669708 |

| RS/F | 0669711 |

| RS/G | 0669712 |

|

Model

|

INJECT 2K 230032 |

| Pressure ratio | 32:1 |

| Output per cycle | 180 ccm (6 fl.oz.) |

| Max. inbound air pressure | 8 bar (116 psi) |

| Max. operating pressure | 256 bar (3,713 psi) |

| Order number | |

| N/G | 0669710 |

|

Model

|

INJECT 2K 230040 |

| Pressure ratio | 40:1 |

| Output per cycle | 144 ccm (4.8 fl.oz.) |

| Max. inbound air pressure | 8 bar (116 psi) |

| Max. operating pressure | 320 bar (4,641 psi) |

| Order number | |

| RS/G | 0669713 |

B - On container, D - on tripod, F - on chassis, G - on rack, H - on lift truck,

GZ - On Rack with feed funnel, W - on wall mount, ASL - suction tube, DAS - Direct suction

Fields Of Application

Mining

Building renovation

Pipes and pipelines

Building and corrosion protection

Tunnels

Building and civil engineering

Materials

- 2K injection resins

- Polyurethane resins

- Silicate resins

- Polyurethane injection foam resins

- PUR

- Polyurethane Combi Resins

- Polyurethane injection resins

- PUR Casting foam resins

- acid curing foams

- Acylatgele

Our 2K piston pump with exchangeable mixing ratio.

Due to the positive control and always the same switching points, you get the perfect dosing with the WIWA INJECT 2K 230. It is strongly characterized by its high delivery rate. In addition to the standard mixing ratio of 1:1, over 100 other mixing ratios are possible by replacing the material pumps. Aqueous and low-viscosity as well as high-viscosity materials are no problem.

Suitable accessories

Selection of project references

|

Model

|

INJECT 2K 230030 |

| Pressure ratio | 30:1 |

| Output per cycle | 194 ccm (6.5 fl.oz.) |

| Max. inbound air pressure | 8 bar (116 psi) |

| Max. operating pressure | 240 bar (3,481 psi) |

| Order numbers | |

| N/G | 0669709 |

| N/F | 0669708 |

| RS/F | 0669711 |

| RS/G | 0669712 |

|

Model

|

INJECT 2K 230032 |

| Pressure ratio | 32:1 |

| Output per cycle | 180 ccm (6 fl.oz.) |

| Max. inbound air pressure | 8 bar (116 psi) |

| Max. operating pressure | 256 bar (3,713 psi) |

| Order number | |

| N/G | 0669710 |

|

Model

|

INJECT 2K 230040 |

| Pressure ratio | 40:1 |

| Output per cycle | 144 ccm (4.8 fl.oz.) |

| Max. inbound air pressure | 8 bar (116 psi) |

| Max. operating pressure | 320 bar (4,641 psi) |

| Order number | |

| RS/G | 0669713 |

B - On container, D - on tripod, F - on chassis, G - on rack, H - on lift truck,

GZ - On Rack with feed funnel, W - on wall mount, ASL - suction tube, DAS - Direct suction

Fields Of Application

Mining

Building renovation

Pipes and pipelines

Building and corrosion protection

Tunnels

Building and civil engineering

Materials

- 2K injection resins

- Polyurethane resins

- Silicate resins

- Polyurethane injection foam resins

- PUR

- Polyurethane Combi Resins

- Polyurethane injection resins

- PUR Casting foam resins

- acid curing foams

- Acylatgele