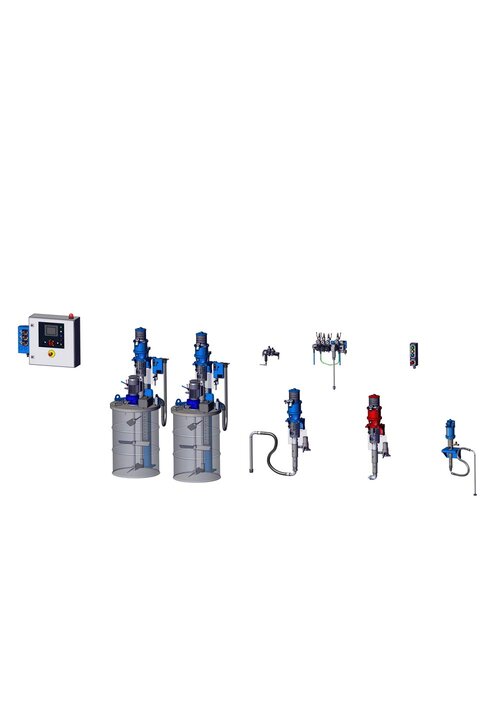

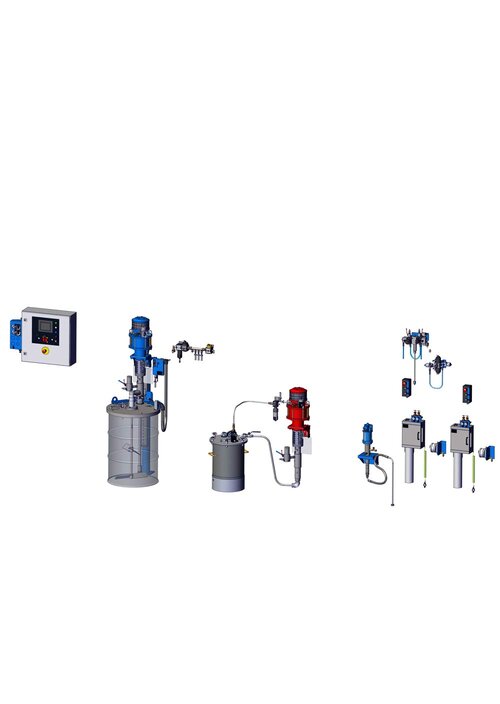

WIWA FLEXIMIX 2 PHOENIX GX

- All material-carrying parts are stainless

- Intuitively operable touch screen display

- Electronic 2K mixing and dosing units for up to 4 components

Description

The next generation of electronic 2K mixing and dosing units for up to 4 components.

Easy and quick to learn operation of the unit via the 3.5 or 5 inch color touch screen display.

All operating elements such as the pressure setting of the material pumps, the rinsing pump and the atomizing air are positioned on the front panel, just like the USB port and the high-pressure filter, and are thus centrally accessible thanks to the new equipment design.

All material-carrying parts of the FLEXIMIX 2 are rust-free, so that water-based paints can also be processed without any problems.

A mixing unit with new high-pressure filters was developed especially for the WIWA FLEXIMIX series. The result: no crystallization when using isocyanate and easy adjustment of the dosage to mixing ratios and viscosities.

The new multifunctional rack allows the unit to be upgraded with optional accessories such as material fluid heaters, feed tanks, rinsing pumps or additional material pumps. On request, the multifunction rack is also available in a mobile version.

With the new WIWA FLEXIMIX unit, all application methods such as Airless, AirCombi, HVLP and electrostatic as well as the conventional spraying methods can be used.

Technical data:

Volumetric mixing ratios: 0.5:1 to 17:1

Pressure ratio: 10:1 to 52:1

Maximum operating pressure: up to 416 bar

Controllable components: up to 4

Suitable accessories

Technical Data

Fields Of Application

Insulation

Railcar construction

Chemical Industry

Apparatus and mechanical engineering

Steel Construction

Joineries

Pipes and pipelines

Painting and varnishing companies

Building and corrosion protection

General Industry

Wood and furniture industry

The next generation of electronic 2K mixing and dosing units for up to 4 components.

Easy and quick to learn operation of the unit via the 3.5 or 5 inch color touch screen display.

All operating elements such as the pressure setting of the material pumps, the rinsing pump and the atomizing air are positioned on the front panel, just like the USB port and the high-pressure filter, and are thus centrally accessible thanks to the new equipment design.

All material-carrying parts of the FLEXIMIX 2 are rust-free, so that water-based paints can also be processed without any problems.

A mixing unit with new high-pressure filters was developed especially for the WIWA FLEXIMIX series. The result: no crystallization when using isocyanate and easy adjustment of the dosage to mixing ratios and viscosities.

The new multifunctional rack allows the unit to be upgraded with optional accessories such as material fluid heaters, feed tanks, rinsing pumps or additional material pumps. On request, the multifunction rack is also available in a mobile version.

With the new WIWA FLEXIMIX unit, all application methods such as Airless, AirCombi, HVLP and electrostatic as well as the conventional spraying methods can be used.

Technical data:

Volumetric mixing ratios: 0.5:1 to 17:1

Pressure ratio: 10:1 to 52:1

Maximum operating pressure: up to 416 bar

Controllable components: up to 4

Suitable accessories

Fields Of Application

Insulation

Railcar construction

Chemical Industry

Apparatus and mechanical engineering

Steel Construction

Joineries

Pipes and pipelines

Painting and varnishing companies

Building and corrosion protection

General Industry

Wood and furniture industry