WIWA 2K GLASSFLAKE SYSTEM GX

- Monitoring function before / during spraying

- Very high productivity and short payback time

- Less wear, rinsing effort and material consumption

Description

Ideal for Corrosion Protection

High-performance glassflake materials combined with optimum WIWA processing technology are the prerequisite for successful corrosion protection measures.

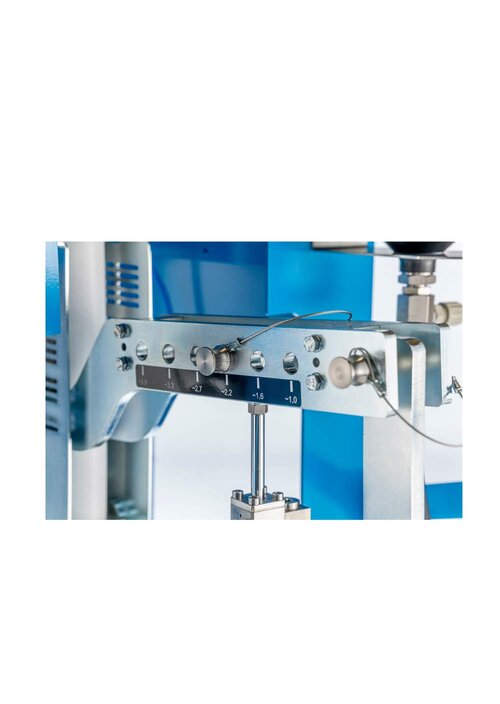

With the compact WIWA 2K GLASSFLAKE UNIT GX, which is suitable for ATEX zone 1, the product can be applied reliably. Through the dosing unit, the correct mixing ratio is checked before spraying. Due to the 2K processing, wear, rinsing effort as well as material consumption are significantly reduced.

There is no need for time-consuming cleaning as with 1K processing, and only the material that is actually used is mixed. The hardener is added undiluted and can be continuously adjusted. Your advantage: process reliability and cost optimization!

Suitable accessories

Technical Data

|

WIWA 2K GLASSFLAKE SYSTEM GX

|

|

| Pressure ratio | 48:1 |

| Output per cycle | 275 ccm (9.2 fl.oz.) |

| Max. inbound air pressure | 8 bar (116 psi) |

| Max. operating pressure | 384 bar (5,569 psi) |

| Order numbers | |

| ATEX Zone 1 | 0671130 |

| Attachment kit forklift lug | 0663298 |

| Attachment kit chassis | 0671159 |

| Attachment kit with agitator | 0664191 |

| stroke counter | 0672605 |

B - On container, D - on tripod, F - on chassis, G - on rack, H - on lift truck,

GZ - On Rack with feed funnel, W - on wall mount, ASL - suction tube, DAS - Direct suction

Fields Of Application

Insulation

Offshore industry

Wind power industry

Building and corrosion protection

Marine Industry

General Industry

Materials

- Glass Flake filled Polyester coating

- Polyester coating (unfilled)

- Polyester filler

- Other materials with 1-3% dosage

Ideal for Corrosion Protection

High-performance glassflake materials combined with optimum WIWA processing technology are the prerequisite for successful corrosion protection measures.

With the compact WIWA 2K GLASSFLAKE UNIT GX, which is suitable for ATEX zone 1, the product can be applied reliably. Through the dosing unit, the correct mixing ratio is checked before spraying. Due to the 2K processing, wear, rinsing effort as well as material consumption are significantly reduced.

There is no need for time-consuming cleaning as with 1K processing, and only the material that is actually used is mixed. The hardener is added undiluted and can be continuously adjusted. Your advantage: process reliability and cost optimization!

Suitable accessories

|

WIWA 2K GLASSFLAKE SYSTEM GX

|

|

| Pressure ratio | 48:1 |

| Output per cycle | 275 ccm (9.2 fl.oz.) |

| Max. inbound air pressure | 8 bar (116 psi) |

| Max. operating pressure | 384 bar (5,569 psi) |

| Order numbers | |

| ATEX Zone 1 | 0671130 |

| Attachment kit forklift lug | 0663298 |

| Attachment kit chassis | 0671159 |

| Attachment kit with agitator | 0664191 |

| stroke counter | 0672605 |

B - On container, D - on tripod, F - on chassis, G - on rack, H - on lift truck,

GZ - On Rack with feed funnel, W - on wall mount, ASL - suction tube, DAS - Direct suction

Fields Of Application

Insulation

Offshore industry

Wind power industry

Building and corrosion protection

Marine Industry

General Industry

Materials

- Glass Flake filled Polyester coating

- Polyester coating (unfilled)

- Polyester filler

- Other materials with 1-3% dosage