WIWA FLEXIMIX GX PFP

- Variable mixing ratio

- Clear display of all system parameters on large screen

- Pressure vessels directly heated with strong heating power

Description

Powerful fire protection, electronically controlled

With the WIWA FLEXIMIX GX PFP, we introduce a new multi-component system in the field of passive fire protection for enormous area outputs and high layer thicknesses - with a variably adjustable, precisely maintained mixing ratio.

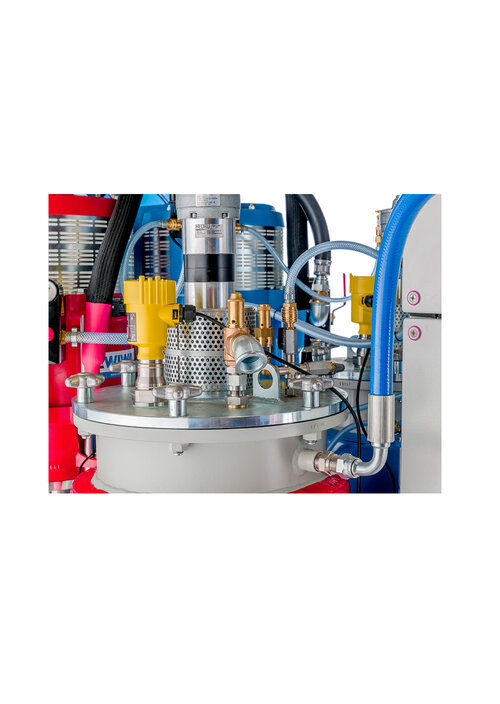

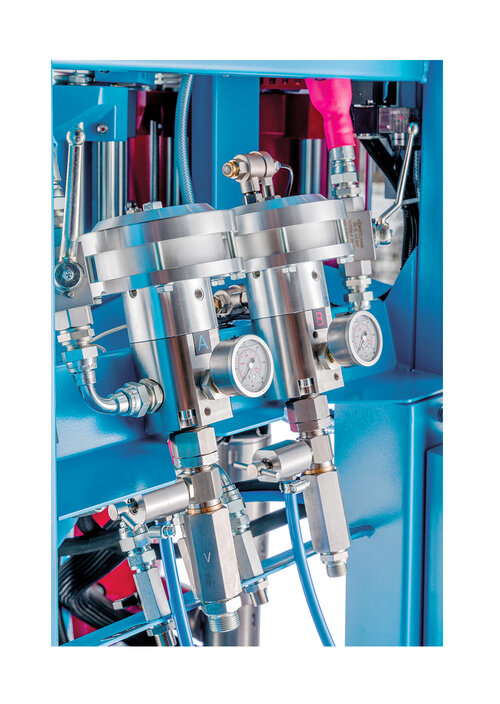

To ensure the correct mixing ratio, operation of the FLEXIMIX GX PFP is weight- or volume-based. Ratio checks are quick and easy to perform and save time and material, as cost-intensive rework is no longer required. The level of the material to be processed is determined by radar sensor and can therefore always be read in real time on the display.

The high-performance series comes as standard on a forklift frame with hose holder and crane lugs, making it amazingly mobile and virtually limitless in use. For even more flexibility, we also offer an extension to the mobile rack.

Monitoring is carried out via Omron PLC, whereby further operating data such as spraying pressure, temperature, mixing ratios and consumption quantities can be recorded via the WIWA DATALOGGER. In addition to the clear display, operation is generally very simple and can be learned within a short time.

The FLEXIMIX GX PFP already operates ex works with five heating circuits, namely for components A and B, pressure vessels A and B, and the hose package. Since the material pressure vessels are each heated directly with a 4 kW tubular heater, the heating time is short and the temperature control is accurate. On request, the unit can be extended by further material fluid heaters and thus modularly adapted to the respective requirements. The large material cross-sections also mean that less pressure is lost. The result: an even higher area output!

Especially when different, even more demanding 2K fire protection materials are to be processed in alternation, the FLEXIMIX GX PFP convinces with its electronic control, with which different mixing ratios can be realized in seconds.

Suitable accessories

Technical Data

|

WIWA FLEXIMIX GX PFP

|

|

| Pressure ratio | 75:1 |

| Max. output | 11.5 l/min (3 gallon/min) |

| Max. inbound air pressure | 6.5 bar (94 psi) |

| Max. operating pressure | 450 bar (6,527 psi) |

| Order number | |

| 0670030 | |

B - On container, D - on tripod, F - on chassis, G - on rack, H - on lift truck,

GZ - On Rack with feed funnel, W - on wall mount, ASL - suction tube, DAS - Direct suction

Fields Of Application

Automotive

Fire protection

Steel Construction

Building and corrosion protection

General Industry

Materials

- (Epoxy) fire protection materials

Powerful fire protection, electronically controlled

With the WIWA FLEXIMIX GX PFP, we introduce a new multi-component system in the field of passive fire protection for enormous area outputs and high layer thicknesses - with a variably adjustable, precisely maintained mixing ratio.

To ensure the correct mixing ratio, operation of the FLEXIMIX GX PFP is weight- or volume-based. Ratio checks are quick and easy to perform and save time and material, as cost-intensive rework is no longer required. The level of the material to be processed is determined by radar sensor and can therefore always be read in real time on the display.

The high-performance series comes as standard on a forklift frame with hose holder and crane lugs, making it amazingly mobile and virtually limitless in use. For even more flexibility, we also offer an extension to the mobile rack.

Monitoring is carried out via Omron PLC, whereby further operating data such as spraying pressure, temperature, mixing ratios and consumption quantities can be recorded via the WIWA DATALOGGER. In addition to the clear display, operation is generally very simple and can be learned within a short time.

The FLEXIMIX GX PFP already operates ex works with five heating circuits, namely for components A and B, pressure vessels A and B, and the hose package. Since the material pressure vessels are each heated directly with a 4 kW tubular heater, the heating time is short and the temperature control is accurate. On request, the unit can be extended by further material fluid heaters and thus modularly adapted to the respective requirements. The large material cross-sections also mean that less pressure is lost. The result: an even higher area output!

Especially when different, even more demanding 2K fire protection materials are to be processed in alternation, the FLEXIMIX GX PFP convinces with its electronic control, with which different mixing ratios can be realized in seconds.

Suitable accessories

|

WIWA FLEXIMIX GX PFP

|

|

| Pressure ratio | 75:1 |

| Max. output | 11.5 l/min (3 gallon/min) |

| Max. inbound air pressure | 6.5 bar (94 psi) |

| Max. operating pressure | 450 bar (6,527 psi) |

| Order number | |

| 0670030 | |

B - On container, D - on tripod, F - on chassis, G - on rack, H - on lift truck,

GZ - On Rack with feed funnel, W - on wall mount, ASL - suction tube, DAS - Direct suction

Fields Of Application

Automotive

Fire protection

Steel Construction

Building and corrosion protection

General Industry

Materials

- (Epoxy) fire protection materials